Factory Facility

QQE Technology Co., LTD. (QQE) was founded in 2003.

It is the professional design and manufacturer of Lithium ,Lithium-iron, and Lead-acid battery chargers. It has more than 20 years of professional R&D and production teams. The production base is in Shipai Town, Dongguan. Our company are with ISO international standards, we have 17,000 square meters in the manufacturing site. The factory has the most advanced manufacturing and inspection equipment such as SMD, AI, Wave solder, AOI, and ATE, as well as the most complete production lines and manufacturing capabilities. The factory is bright and clean, and has passed ISO 9001, ISO 14001, ISO 45001 and TUV certification. The monthly production capacity can reach up to 52,000 battery chargers, quantity and quality can pursue high efficiency and performance, and pay more attention to high-quality management.

QQE is committed to the green energy industry as the starting point, and has developed a variety of battery chargers with output power ranging from 60W to 7200W to provide power battery charging needs for different industries, such as E-Bike, E-Moto, E-scooters, sweeper, electric cleaning vehicles and other related products. It reduces the pollution of carbon dioxide and exhaust gas generated by fuels to the environment, improves energy conservation and achieves sustainable environmental protection.

Factory machinery and equipment with well-planned production line

Factory Scenes

- DIP professional artificial plug-in process.

- Professionals use SMT technology to mount components on the surface of the circuit board.

- Professionals put the PCB boards into wave soldering equipment for high-temperature soldering.

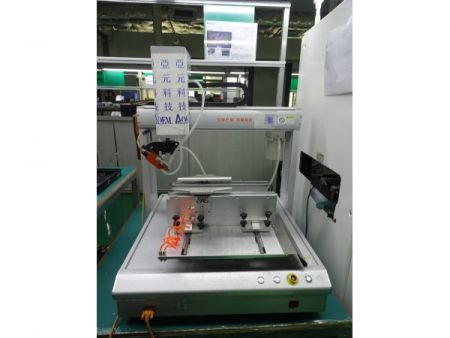

- Inspectors use AOl fully automated optical inspection of PCB board quality.

- The charger uses Burn-in intelligent monitoring and constant temperature system for aging test.

- The charger is functionally tested using the ATE automatic test system.